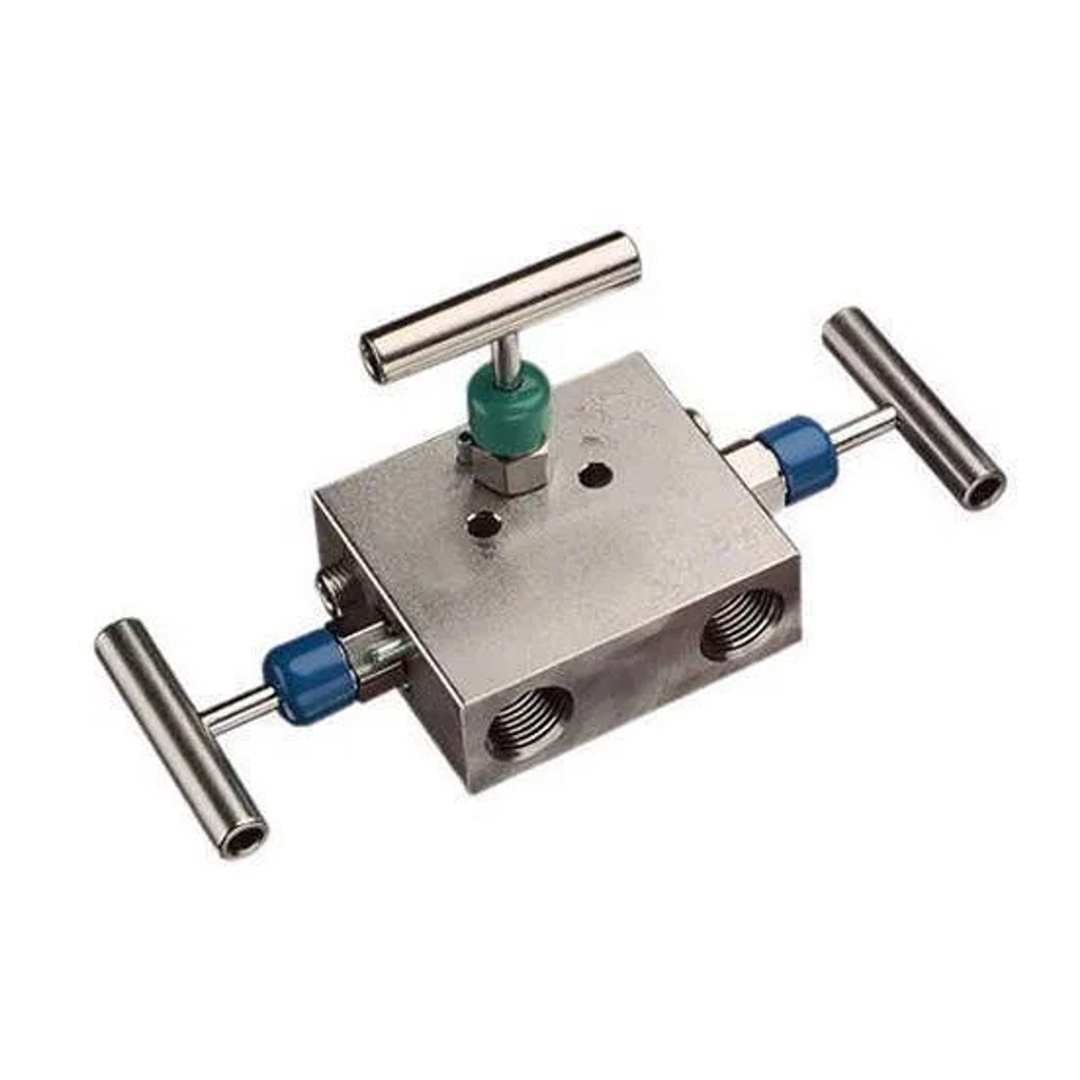

Manifold Valves Manufacturer

Quality Industries is a Leading Manifold Valves Manufacturer, Supplier and Exporter From India. Manifold valves are versatile multi-port assemblies used to streamline the process of controlling and isolating flow in various industrial systems, particularly in instrumentation and process control. These valves are designed to integrate multiple functions into a single compact unit, reducing the need for additional piping and connections. Typically, they are used in conjunction with pressure gauges, transmitters, and differential pressure flow meters, allowing for efficient calibration, isolation, and venting operations. Manifold valves are available in various configurations, such as 2-way, 3-way, and 5-way designs, to suit specific applications. Constructed from robust materials like stainless steel, they ensure reliable performance in high-pressure and corrosive environments, making them essential for industries like oil and gas, petrochemical, and power generation.

Frequently Asked Questions

A manifold valve is a device that combines multiple valves into a single body, used to control the flow of fluids or gases in various industrial processes. It is commonly used in conjunction with pressure instruments like transmitters and gauges.

Manifold valves work by connecting and controlling the flow between instruments and the process line. They allow for isolation, calibration, and venting without interrupting the process.

- 2-Valve Manifold: Typically used for pressure transmitters; allows isolation and calibration.

- 3-Valve Manifold: Commonly used with differential pressure transmitters; includes two isolation valves and one equalizing valve.

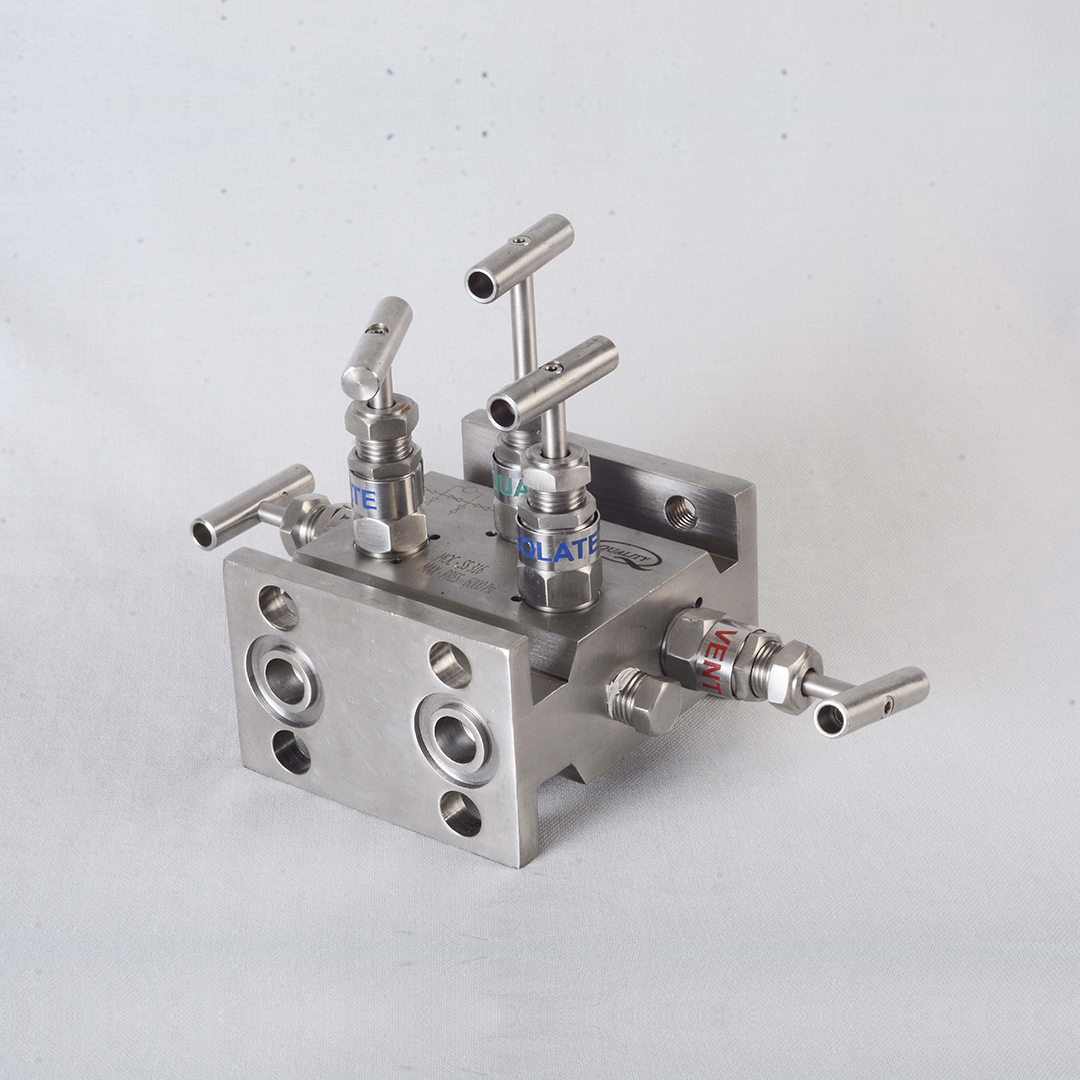

- 5-Valve Manifold: Used for differential pressure transmitters; includes two isolation valves, two equalizing valves, and one vent valve.

Manifold valves are widely used in industries such as:

- Oil and gas

- Chemical processing

- Power generation

- Water treatment

- Space-saving: Combines multiple valves into a single unit, reducing space requirements.

- Efficiency: Simplifies the installation and maintenance of instrumentation systems.

- Safety: Provides isolation, venting, and calibration without disturbing the process.

Yes, manifold valves are designed to handle high-pressure environments, making them suitable for various industrial applications.