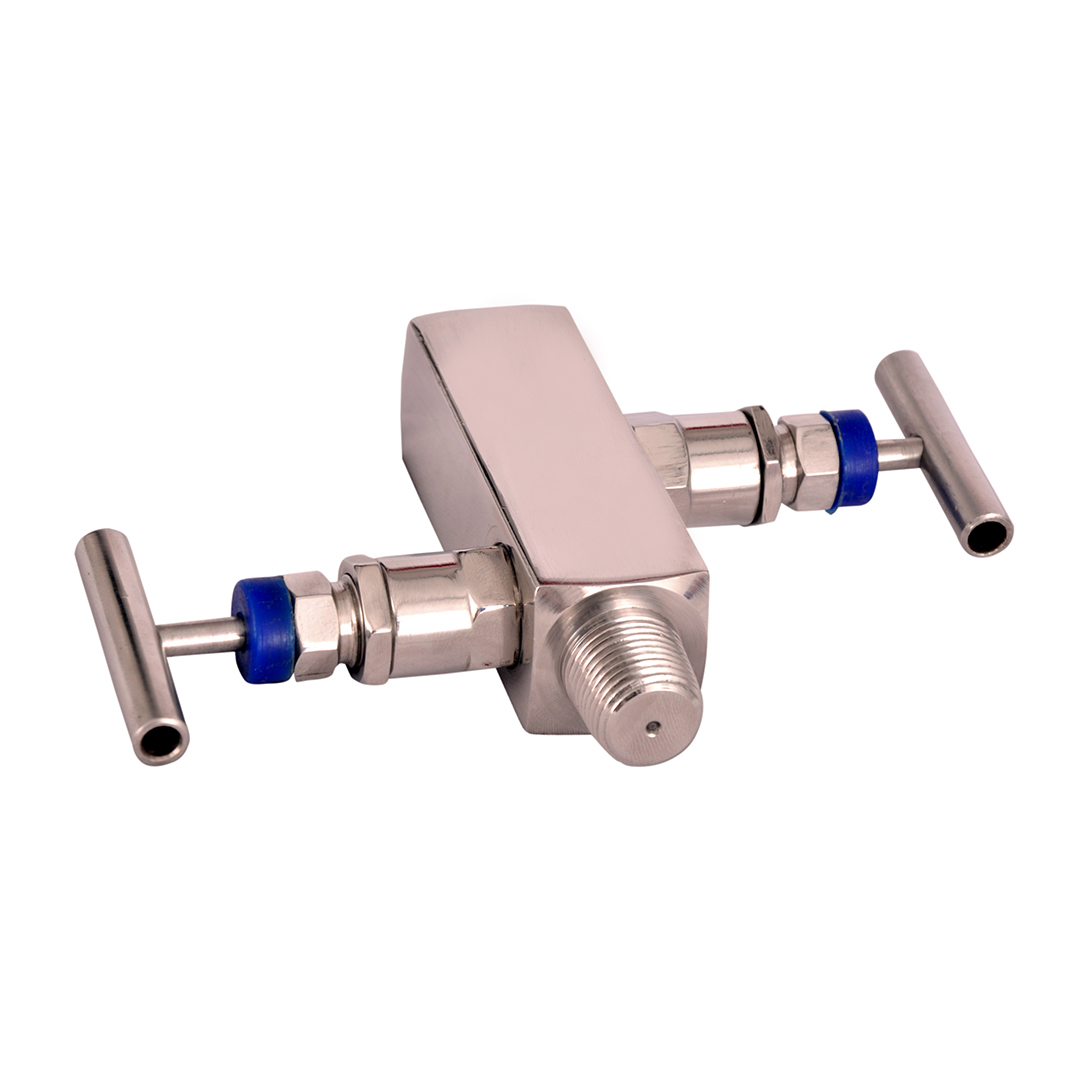

Double Block & Bleed Valve (DBB Valve) Manufacturer

Quality Industries is a Leading Double Block & Bleed Valve (DBB Valve) Manufacturer, Supplier and Exporter From India. A Double Block & Bleed Valve (DBB Valve) is a type of valve that provides isolation between two separate process lines and also allows for venting of the area between the two valves. This design offers a significant safety advantage over traditional block and bleed valves by providing redundant isolation and venting capabilities. If one valve fails, the other valve can still isolate the line, reducing the risk of process fluid leakage.

DBB valves are commonly used in applications where the safety of personnel and equipment is critical, such as in the oil and gas industry, chemical processing, and power generation.

Features of Block & Bleed Valve (DBB Valve)

- • Size :1/4”, 3/8”, ½”

- • End Connections :NPT / BSPP / BSPT

- • Material :316 SS / 316L SS / 304 SS / SS 304 L

- • Maximum working Pressure :6000 PSI / 10000 PSI

- • Maximum working Temperature :110° C

Frequently Asked Questions

A Double Block & Bleed (DBB) valve is a single valve that provides dual isolation and a bleed valve to release any trapped pressure between the two isolation points. It is used to ensure complete isolation for maintenance or safety purposes.

The DBB valve works by having two isolation valves and one bleed valve within a single assembly. The two isolation valves block flow from both sides, while the bleed valve allows for the venting of any pressure or fluid trapped between the isolation points.

DBB valves are used in applications requiring high levels of safety and isolation, such as:

- Oil and gas industry

- Chemical and petrochemical processing

- Power generation

- Refining and pipeline systems

DBB valves are made from various materials, including:

- Stainless steel

- Carbon steel

- Duplex stainless steel

- Alloy materials The material selection depends on the operating environment and the type of fluids or gases being handled.

- Enhanced safety: Provides complete isolation to prevent leaks and ensure safe maintenance.

- Space-saving design: Combines multiple valves into a single compact unit, reducing space requirements.

- Cost-effective: Reduces the need for multiple valves and fittings, saving on installation and maintenance costs.

- Ease of maintenance: Simplifies the process of venting and isolating sections of a pipeline or system.

Yes, DBB valves are designed to handle high-pressure applications, making them suitable for use in critical and high-risk environments.