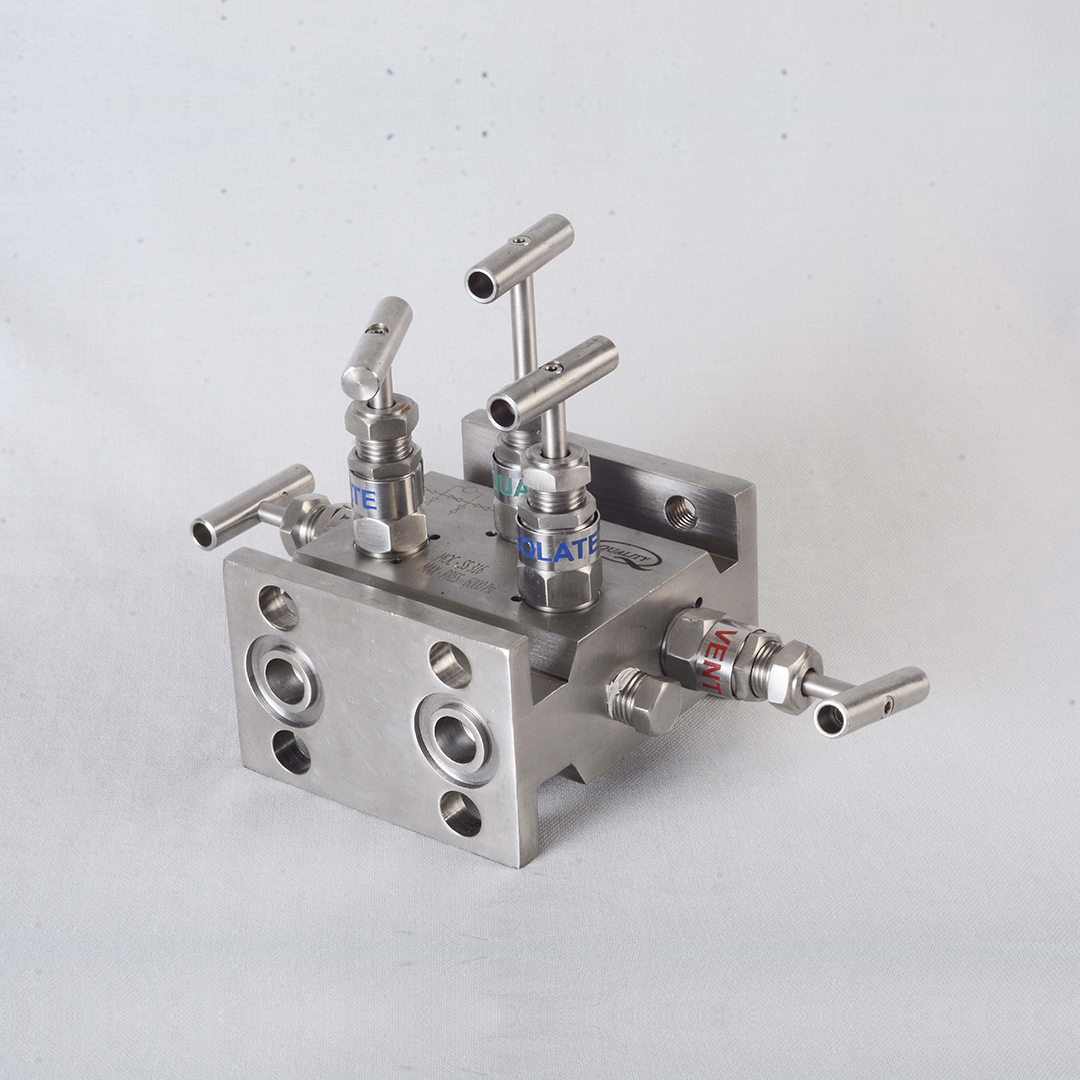

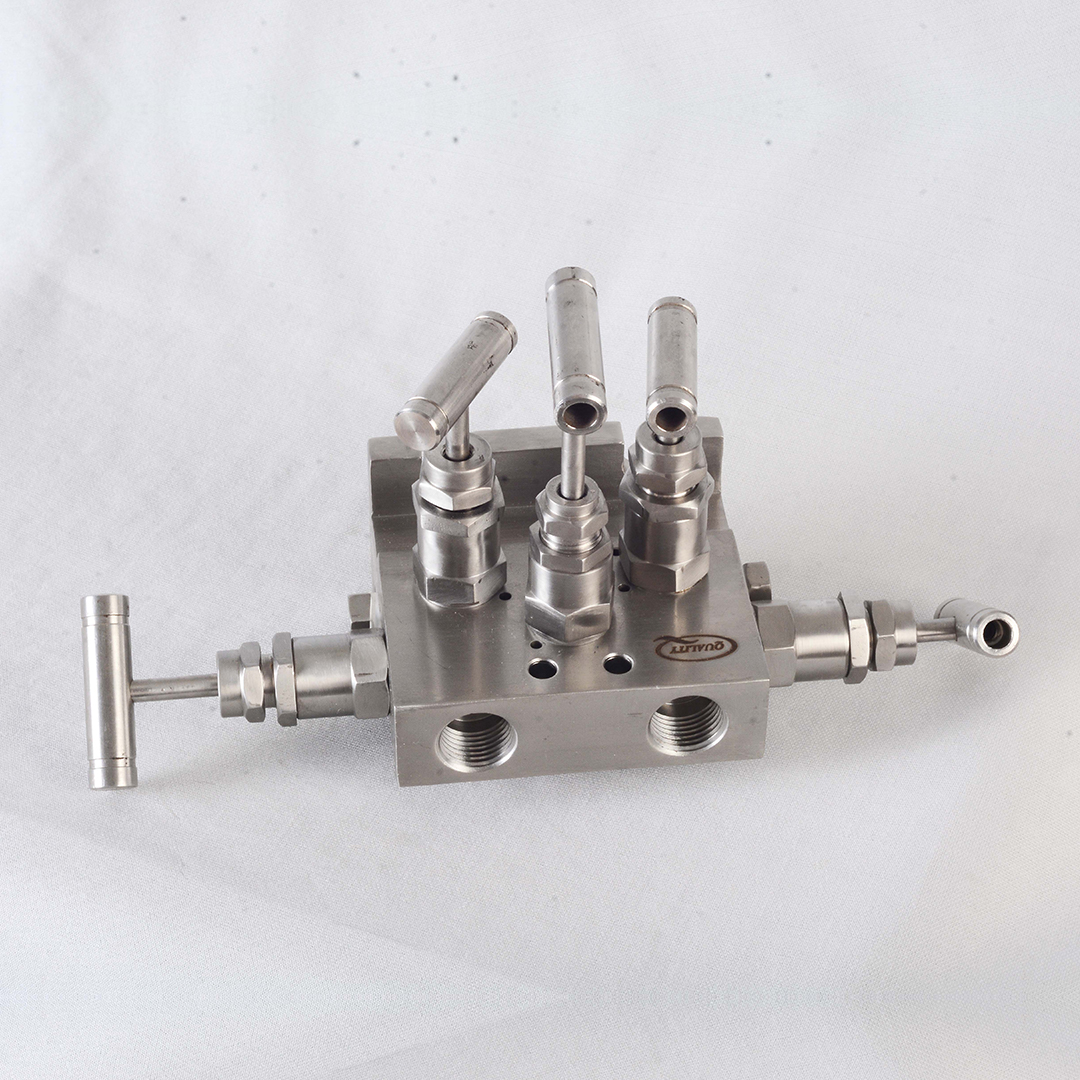

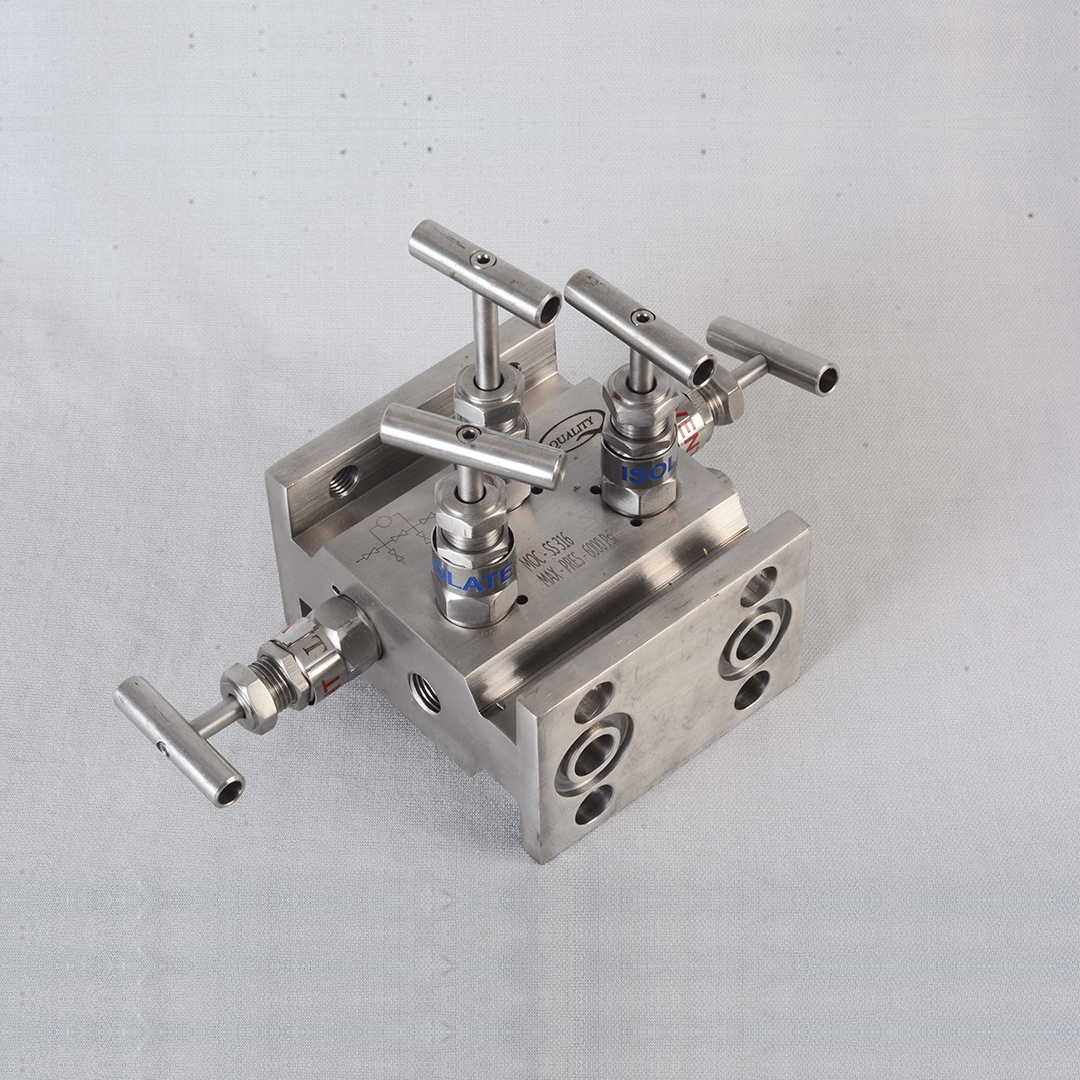

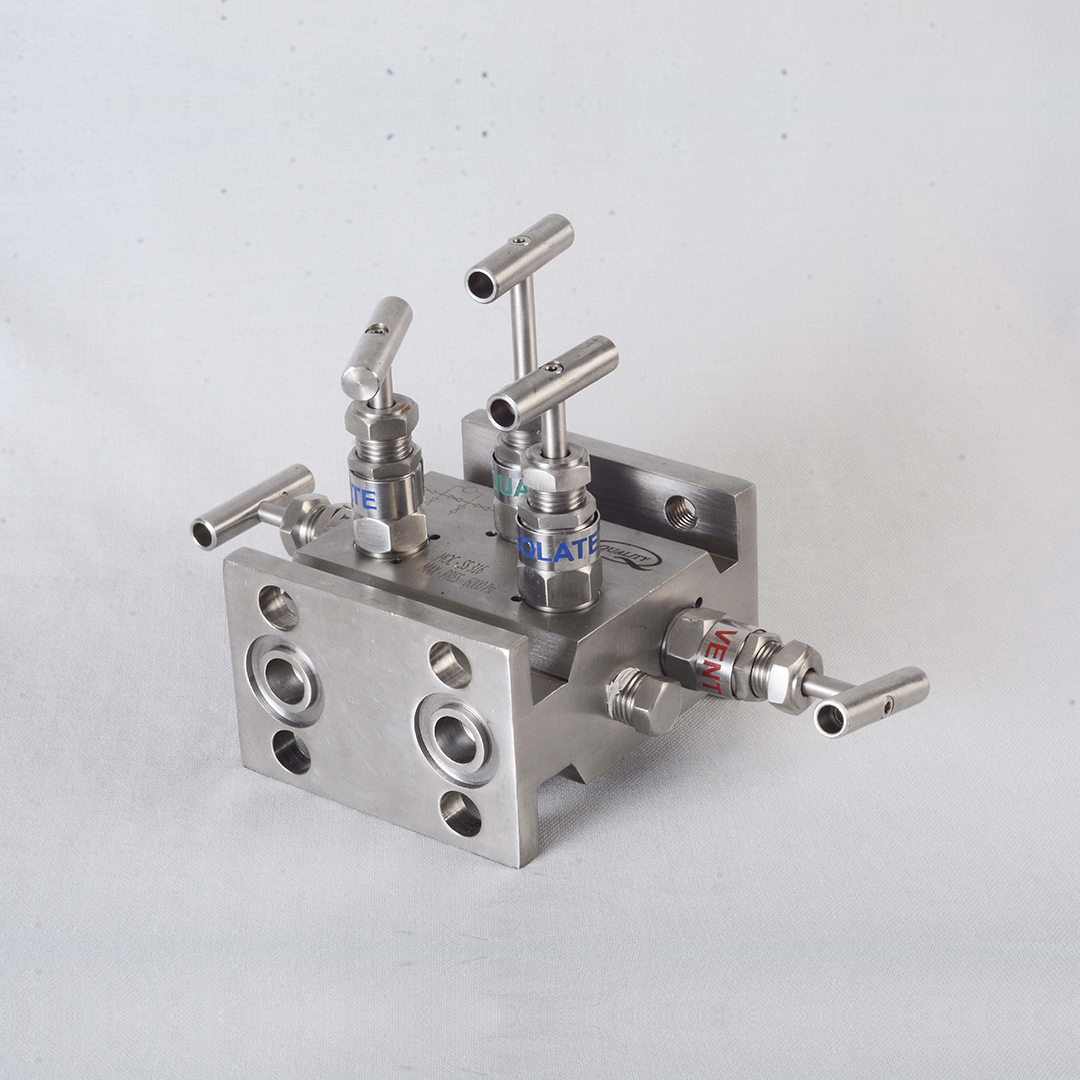

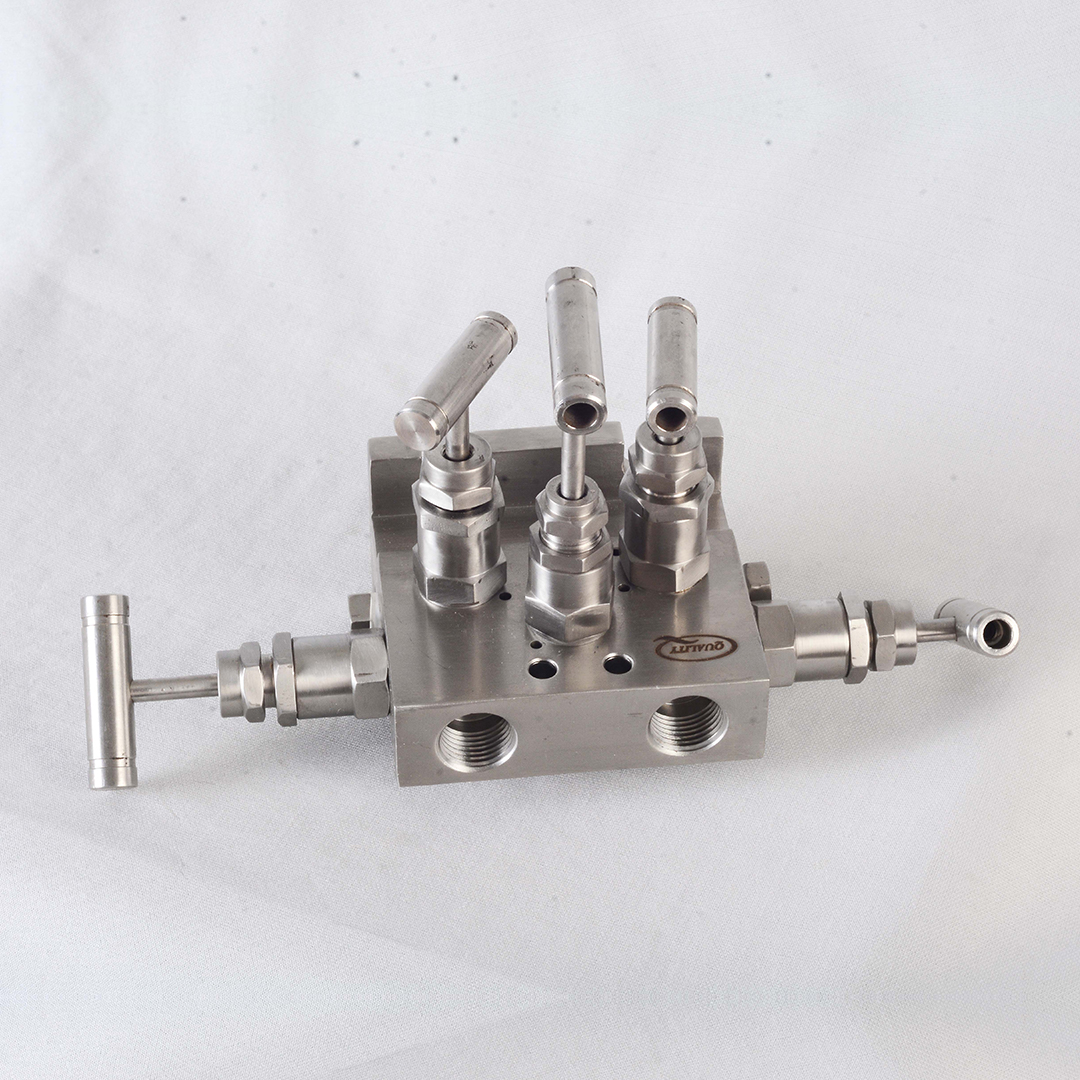

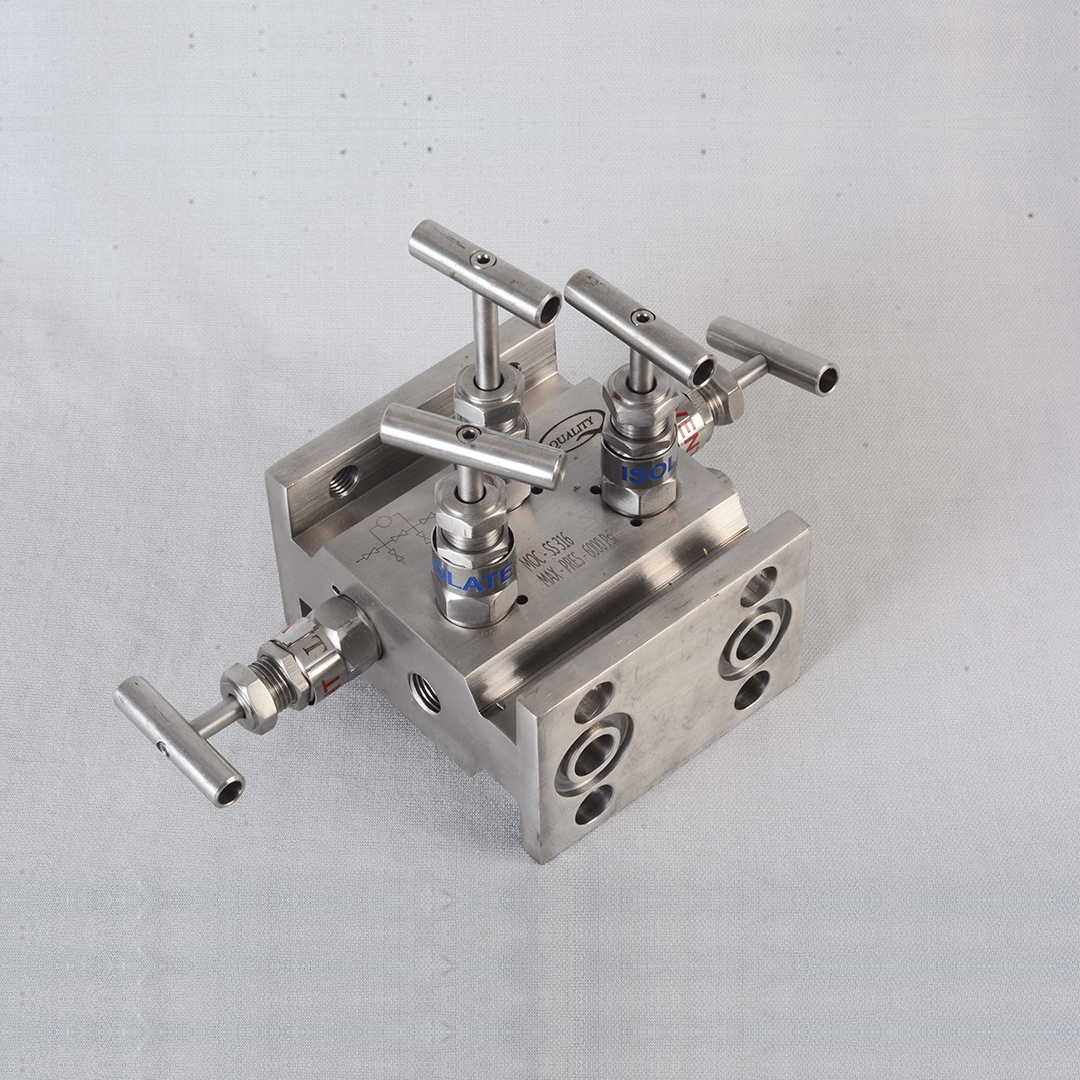

5 Valve Manifold Manufacturer

Quality Industries is a Leading 5 Valve Manifold Manufacturer, Supplier and Exporter From India. QUALITY 5 valve manifolds are also used for differential pressure application. A typical 5-way manifold valve consists of two isolation valve, one equalize and two drain/vent valves integrated in one compact unit. Unlike 3-way valves where a drain plug is used in case a drain port is provided, these have two separate valves provided for drain or test purposes for better vent operation.

Features of 5 Valve Manifold

- • Material: SS 316, SS 316 L, SS304 , SS 304 L

- • Available in various configuration such as pipe to pipe, pipe to flange and flange to flange.

- • Maximum working pressure: 6000 psi, 10,000 psig

- • Maximum: Temperature upto 210°C

- • PTFE standard gland packing, Alternate Graphoil packing for high temperature.

- • Non-Rotating Vee-tip / Ball tip provides repetitive & leak tight shut-off.

Frequently Asked Questions

A 5-valve manifold, commonly used for differential pressure transmitter applications, features two block valves, one equalizer valve, and two vent/drain valves, allowing for process isolation, pressure equalization, venting, and calibration without removing the transmitter.

A 5-way manifold valve, used in differential pressure transmitter applications, allows for isolating, equalizing, and venting process connections, as well as calibrating the transmitter without removing it from the setup.

5-valve manifolds are primarily used with differential pressure transmitters for applications requiring isolation, pressure equalization, venting, and testing.

5 Valve Manifold are made from various materials, including:

- Provides precise pressure measurement and control

- Ensures safe maintenance without system shutdown

- Leak-proof design for high-pressure applications

- Compact and easy to install