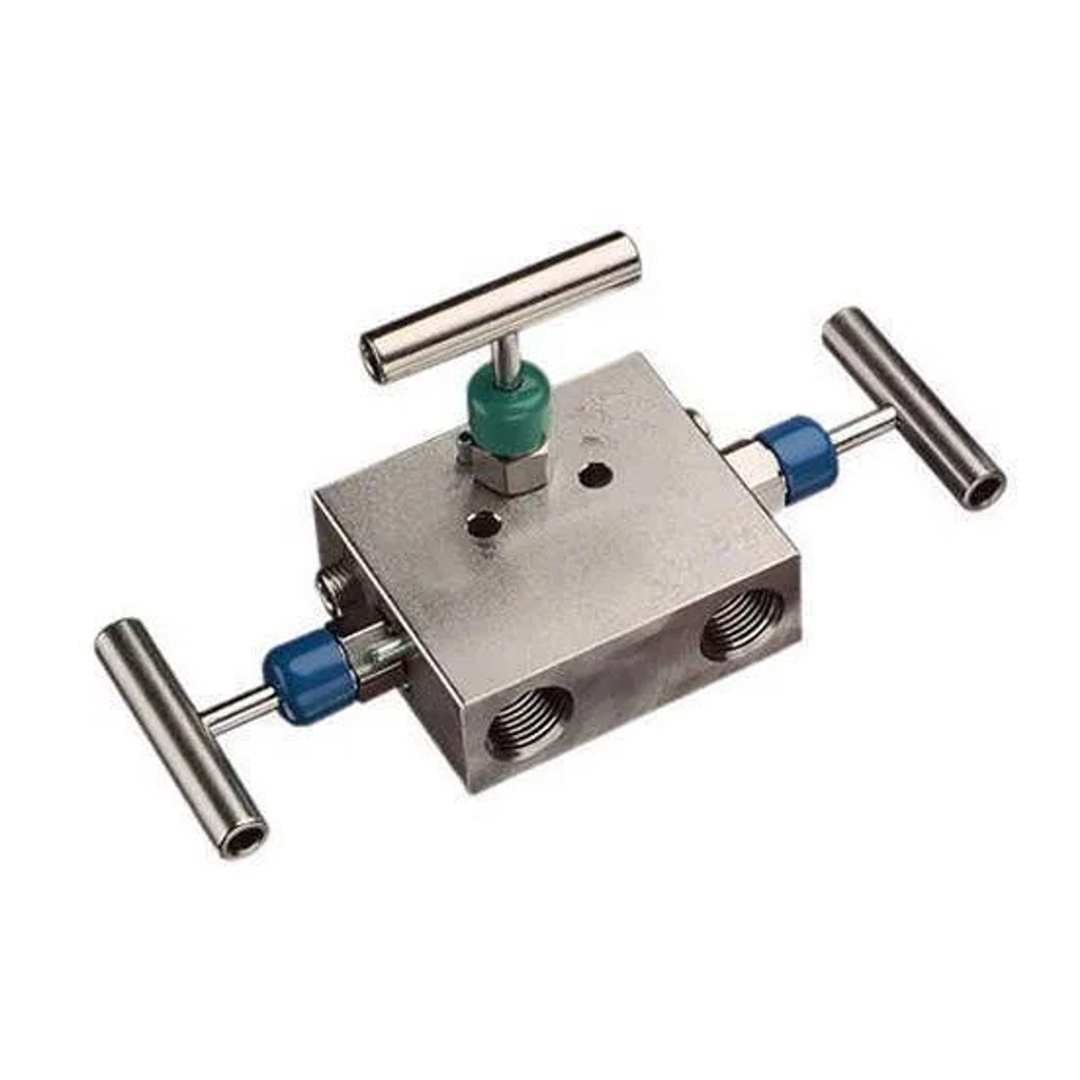

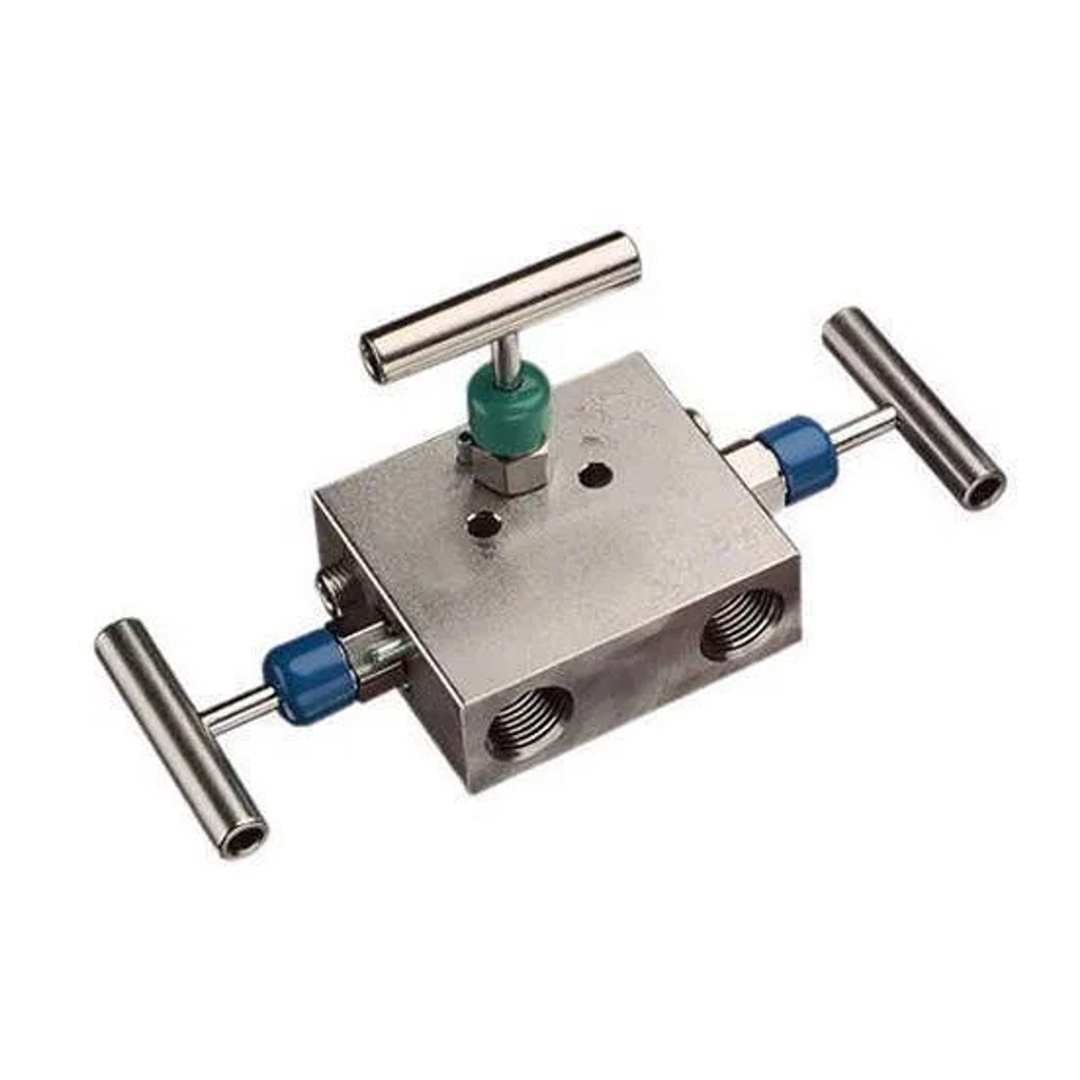

3 Valve Manifold Manufacturer

Quality Industries is a Leading 3 Valve Manifold Manufacturer, Supplier and Exporter From India. QUALITY offer 3 valve manifolds are configured to direct and remote mount with combination of two isolation valves with an equalize valve (bleed port with a plug is optional) consolidated in one compact unit. These valves are designed for differential pressure application and are available in various styles to suit your demand.

A 3-valve manifold is a specialized device used to connect differential pressure transmitters or gauges to the process system, allowing for efficient isolation, equalization, and venting. It features three valves: two block (isolation) valves and one equalizer valve. The block valves are used to isolate the high and low-pressure sides of the transmitter, while the equalizer valve balances the pressure between these sides for zeroing and calibration. This configuration helps prevent damage to sensitive instruments during maintenance and ensures accurate differential pressure readings. Typically constructed from materials like stainless steel for corrosion resistance, 3-valve manifolds are widely used in critical applications within industries such as oil and gas, petrochemical, and power generation, where precise pressure measurement is crucial.

Features of 3 Valve Manifold

- • Material: SS304 ,SS 304 L, SS316, SS 316 L

- • Available in various configuration such as pipe to pipe, pipe to flange and flange to flange.

- • Maximum working pressure: 6000 psi, 10,000 psig.

- • Maximum: Temperature upto 210°C

- • PTFE standard gland packing, Alternate Graphoil packing for high temperature.

- • Non-Rotating Vee-tip / Ball tip provides repetitive & leak tight shut-off.

- • Model: Remote mount and Direct mount

Frequently Asked Questions

A 3-valve manifold, commonly used with differential pressure transmitters, consists of two block valves and one equalizer valve, allowing for isolation, calibration, and purging of the transmitter while preventing over-ranging.

A 3-valve manifold, commonly used with differential pressure (DP) transmitters, features two block valves for process isolation and one equalizer valve for pressure balancing, allowing for safe transmitter removal and zero checks.

3-valve manifolds are primarily used with differential pressure transmitters to allow for isolation, calibration, and purging of the transmitter, while also preventing over-ranging of the instrument.

3 Valve Manifold are made from various materials, including:

- Isolation Valves – To block process pressure during maintenance

- Equalizing Valve – To balance pressure between high and low sides

- Vent/Drain Valve – To release trapped pressure safely